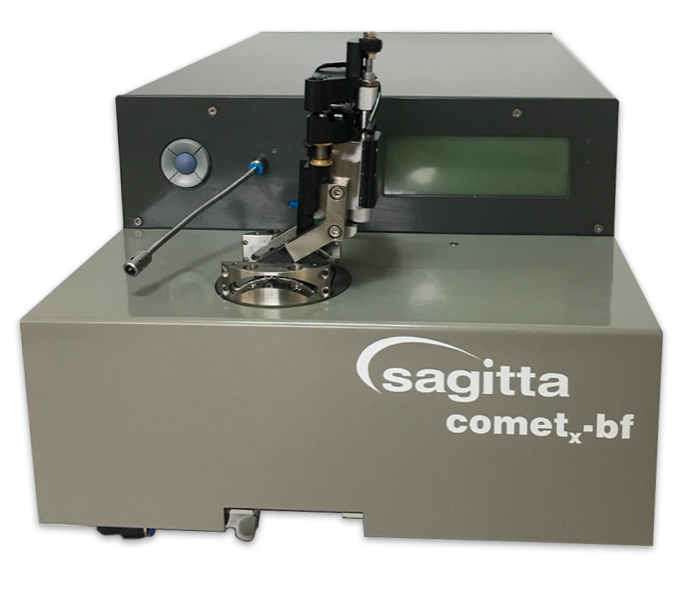

Laser Cleaving & Stripping of Fibers & Ribbons

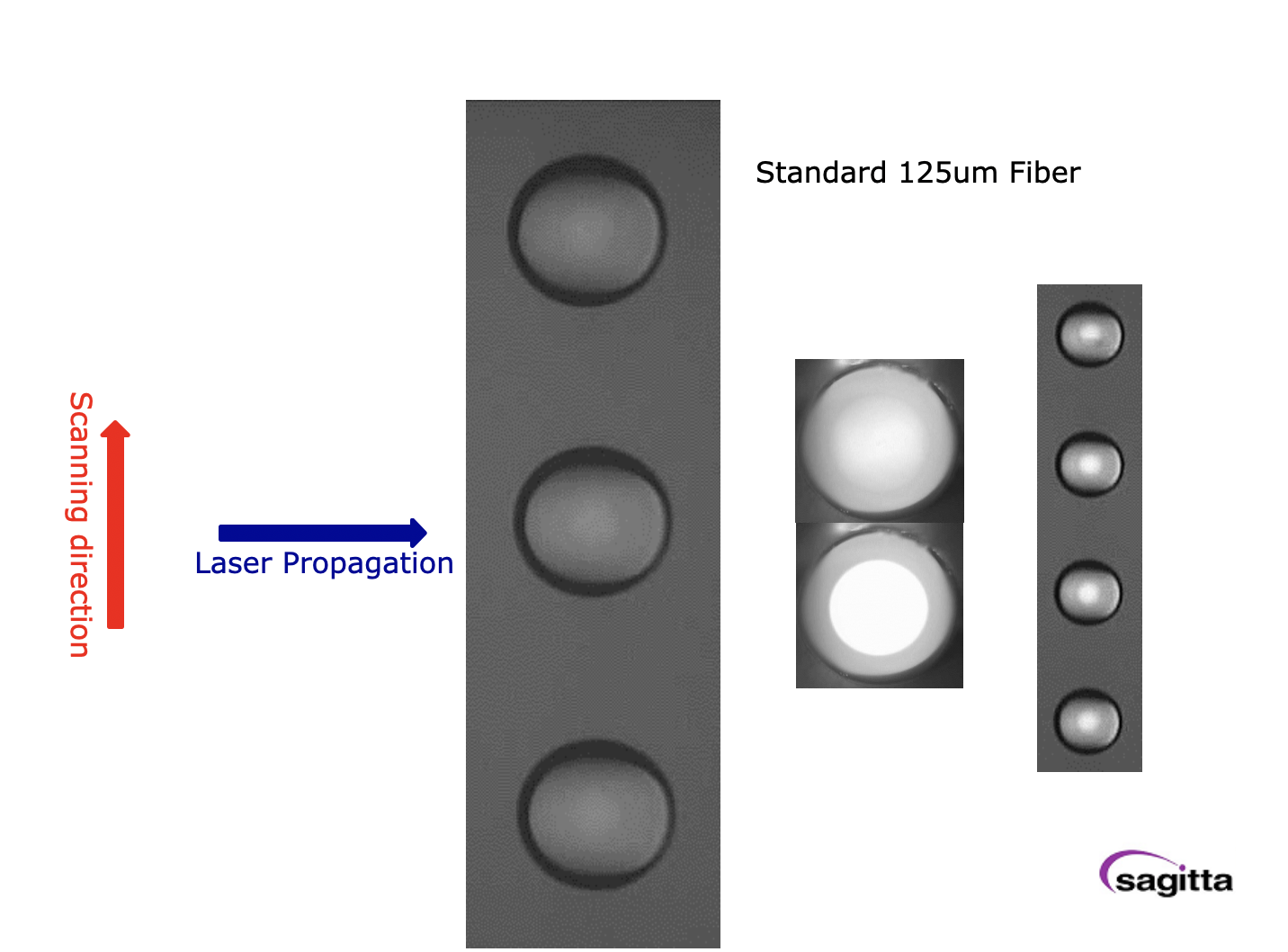

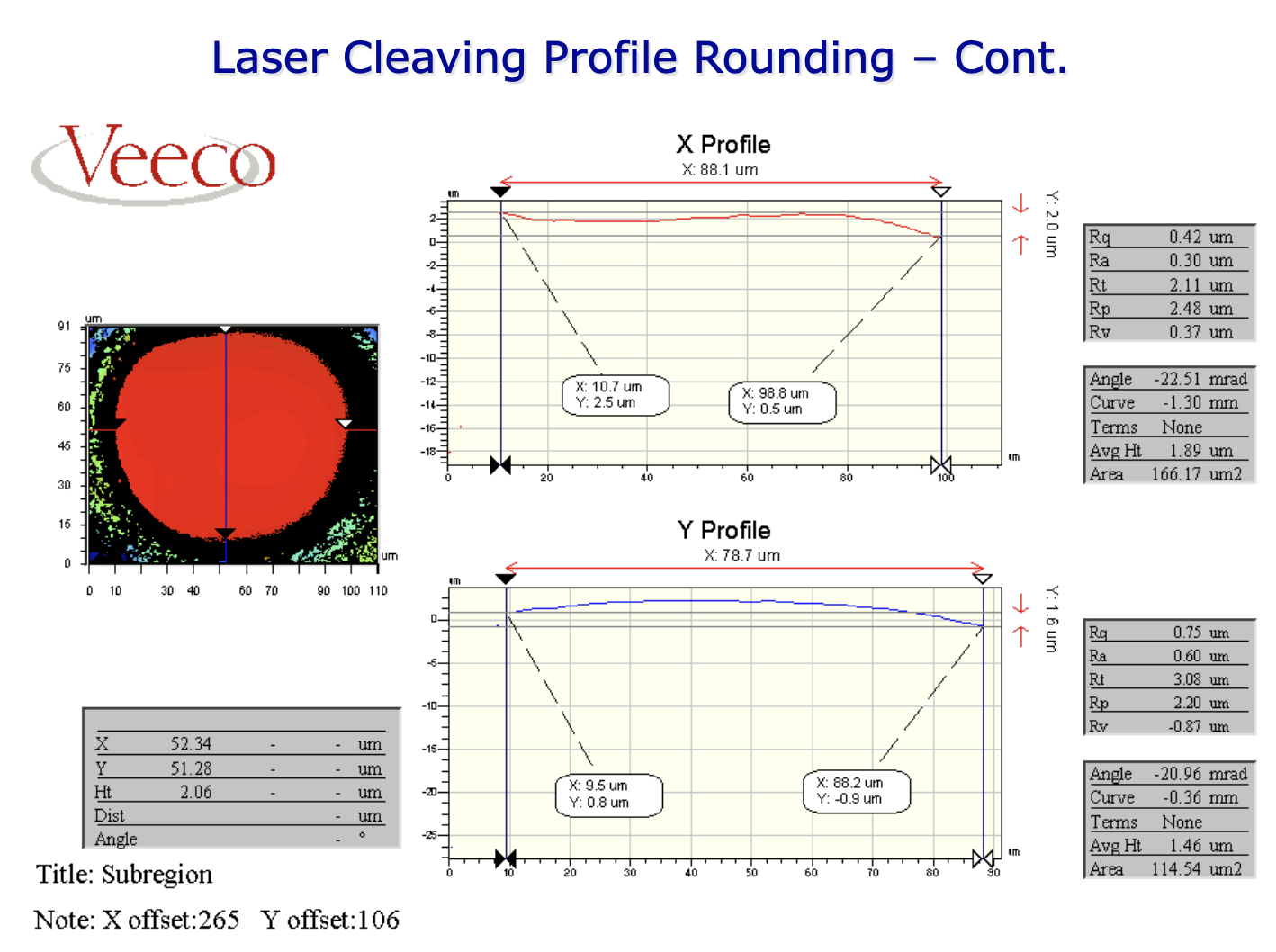

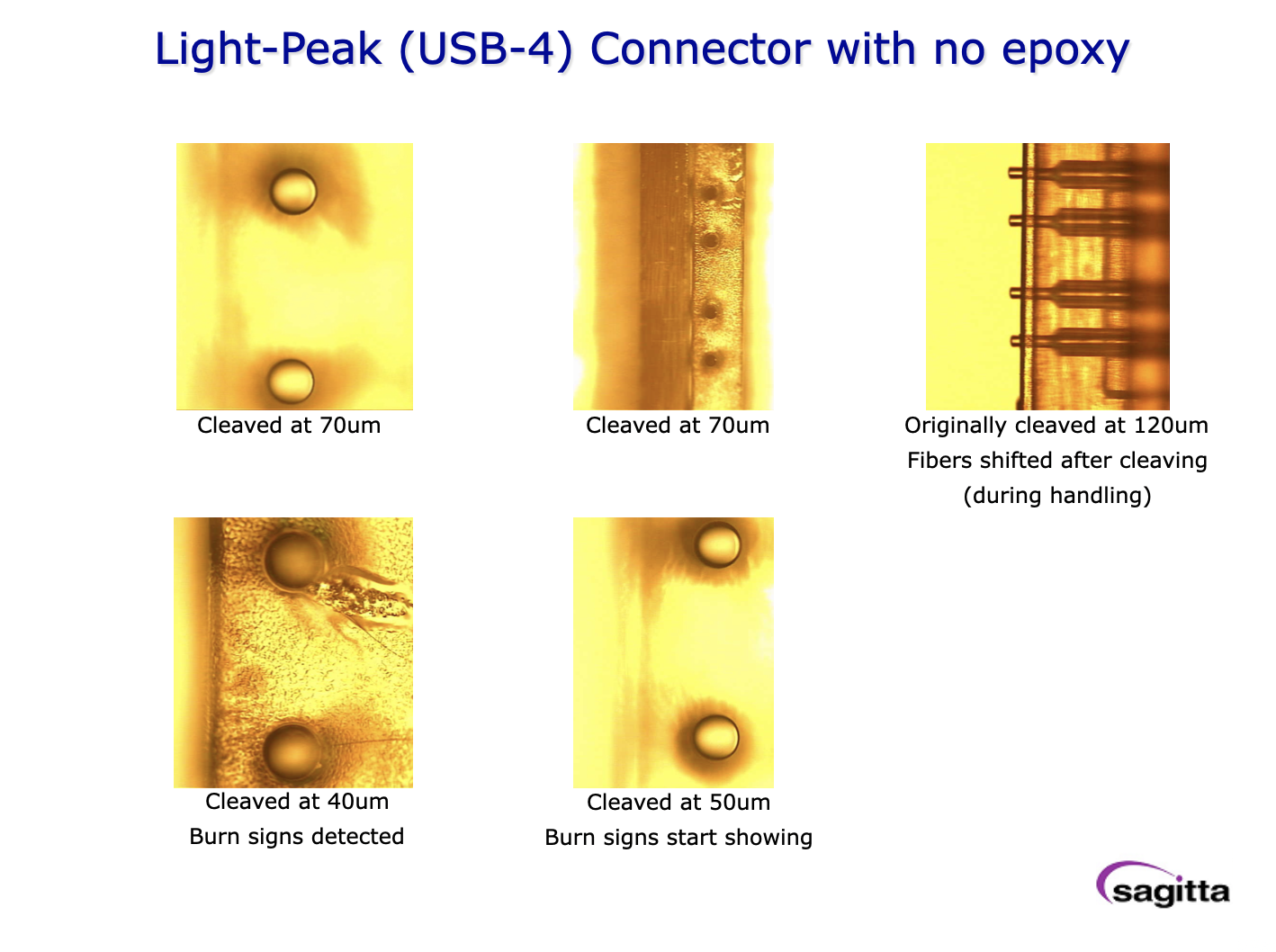

During the termination process, connectors must be cleaved before they can be polished. Laser cleaving increases production yield and connector performance. Laser cleaving has been effectively proven and qualified as more reliable than mechanical connector cleaving. Corning Cable Systems has been using its patented laser cleaving process for many years and has shipped millions of connectors worldwide.